Lights in Pall Mall 1809

|

Bury St Edmunds and Haverhill Gasworks

and

the story of coalgas and the change to natural gas

| 1807 |

In the late 18th century and before 1807, there had been experiments in lighting factories by gas, using an on-site plant. Frederic Winsor believed that it would be much more cost effective to have a central gasworks, with pipes to distribute the gas to various premises or streets.

In London, the first use of gas for street lighting was demonstrated at Pall Mall. The German inventor, Frederic Winsor, set up a gas works and distributed the gas to lighting columns. He would go on to found the Gaslight and Coke Company in London in 1812.

This cartoon of the lights in Pall Mall, by Thomas Rowlandson, was published in 1809, and is taken from Wikipedia.

|

| 1811 |

Before 1834 there was no general pattern of local government. Towns like Bury, Ipswich, Sudbury and Thetford had been given the power to elect a corporation by Royal Charter at various times. Bury's charter was granted in 1606.

In 1811 the corporation had needed to obtain an Act of Parliament to establish Paving and Improvement Commissioners for the town, but only within the urban area bounded by the old town walls and gates. Neither the town council or the Improvement Commissioners had the power to adopt the new street lighting initiatives being discussed at this time. Their priority was paving and draining the town's streets.

|

| 1812 |

In London, the Chartered Gaslight and Coke Company was formed under a private Act of Parliament, and proceeded to spread gas lighting throughout the streets of the city. This innovation quickly proved popular. This company employed an engineer called Samuel Clegg, who was responsible for several early inventions to purify the gas and meter it more accurately. This company also employed John Malam for a time.

|

|

Peckston on Gaslight |

| 1819 |

John Malam had learned the gas business along with Samuel Clegg, working for Frederic Winsor. In 1819 Malam improved upon Clegg's gas meter, and even married his daughter. John Malam would be involved in building many new gasworks over the next decades, and would be the proud sire of a family of future gas engineers.

Also in 1819 Thomas Snowden Peckston published his 400 page treatise on "The Theory and Practice of Gas-Lighting." Its subtitle was, "In Which Is Exhibited an Historical Sketch of the Rise and Progress of the Science; and the Theories of Light, Combustion, and Formation of Coal, With Description of the Most Approved Apparatus for Generating, Collecting, and Distributing, Coal-Gas for Illuminating Purposes." Peckston, like Malam and Clegg, worked for the London Gaslight and Coke company.

|

| 1820 |

In 1820 James Oakes was influential in prompting a new Act of Parliament giving the Paving Commissioners in Bury St Edmunds the right to borrow up to £10,000 to repair and light the streets. However, in the way of government bureaucracy, they were not allowed to borrow more than £8,000 at one time, but a further £4,000 could be borrowed to pay for the costs and expenses of applying for the Act of Parliament. Oakes knew that this would not be enough "to complete the paving and repair which wants and to light next winter."

Nevertheless, the Act also authorised the lighting of streets and houses in the town by gas, including all the necessary works involved in setting up a gasworks and the mains. This would take another 14 years to happen. The 1820 act also extended the Commissioners' remit to the whole area of the Borough of Bury St Edmunds, whereas the 1811 act had limited them to the urban area within the old town gates.

At Norwich a gas works was being built in 1820 to generate gas from oil at St Stephens, but in 1830 this would be replaced by a coal gas works at Thorpe. Ipswich had a coal gas works in operation by 1822. Paris also adopted gas for street lighting in 1820.

|

| 1823 |

By 1823 London had three gas works, supporting 40,000 street lamps in 213 streets. It was now clear that this was a viable form of lighting and a growing industry.

|

| 1825 |

The first town outside London to install gas lighting was Preston, in Lancashire, installed by Joseph Dunn's Preston Gaslight company.

|

|

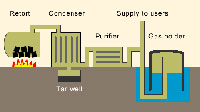

The coalgas process |

| 1830 |

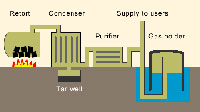

By 1826 all the big cities in the country had their own gas works producing gas for lighting. This diagram illustrates the basic process for producing and storing gas. The diagram shows how gas was stored in a single tank, which effectively floated in a well of water to seal off the gas. When gas demand was low, the tank would fill and rise up out of the well, and it would sink down again as gas was drawn off.

At this early period the by-products of the process like tar and coke were often regarded as a nuisance, and sometimes disposed of into the ground. Even the heating potential of burning gas was ignored, and regarded as a problem which interfered with the generation of light.

By 1830 there were 200 gas companies in operation throughout the country, all concentrating upon street lighting and lighting major public buildings.

|

| 1833 |

The Bury St Edmunds Paving Commissioners agreed that the firm of John Malam and Thomas Snowden Peckston should be allowed to bring Gas Lighting to the town. They would be allowed to lay down gaspipes to supply houses, and to put up Gas Lights in Abbeygate Street. Peckston now bought some land in the Tayfen to build the Gas Works on. (This location was supposed to have once been used for public executions, being just outside the town wall.) The firm would build the works over the next two years and would soon run into financial difficulties.

|

|

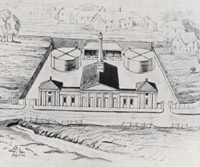

Gas Works in 1834 |

| 1834 |

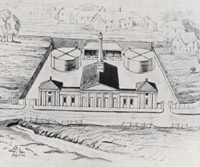

On January 11th, 1834, the Bury St Edmunds Paving, Lighting and Cleansing Commissioners signed a contract with John Malam of Hull, and T S Peckston, for the erection of a Gas Works sufficient to supply gas to public lamps and public and private buildings within the town. The contract provided for further provision as required by the commissioners, and would last for ten years from 1st October, 1834.

Thus, during 1834, Malam and Peckston's firm from Hull built the town of Bury a Gasworks on the edge of Tay Fen, in Tayfen Road. The works cost about £12,000 and were said to be built on the site where at one time criminals were executed. The firm had been allowed to lay down gaspipes to supply houses, and to put up gas lights in Abbeygate Street. The pressure was very low, but the improvement made by the gas lighting of the streets was dramatic.

To make the gas, they heated coal within a closed container so that it could not burn. This produced the gas which was collected in two simple gasholders at the back of the site. The bell shaped covers on these gasholders floated in a bed of water, and could rise and fall as gas levels varied. Tar was a by-product of the process, as was coke, which could also be sold as a fuel.

The coal had to be brought in by canal, and at this time the River Lark had been the local Coal River for over a hundred years, but the wharf and coalyard did not come right into the town. The canalised section ended just outside the Borough boundary at Babwell, which by 1834 was part of the parish of Fornham All Saints. The site is now a carpark on Fornham Road serving the Co-Op store, and the old maltings which is currently, (2012) being converted into flats. Horses and carts would be needed to bring the coal from the Fornham Wharf to the new gasworks.

In 1834 the new Baptist Chapel was being built in Garland Street, and this building was one of the first customers to have gas lighting installed.

|

|

Robert Bevan

|

|

1835

|

By January 1835, Malam and Peckston's Bury St Edmunds Gas company became wound up after only a few months in existence, and so the gasworks were bought by the newly formed Bury St Edmunds Gas Light Company using finance lent by the Improvement Commissioners. The price was £6,000 in cash and £6,000 in fully paid shares in the new company, which T S Peckston now held. Peckston thus owned half of the new company, while Malam took the cash. Peckston also owned an interest in gas companies in Stowmarket, Beccles, Bungay, Lowestoft and Woodbridge. Despite his enthusiasm for this new technology, he over-reached himself and unfortunately he would become insolvent in about 1840.

Although Peckston owned half of the shares, the remainder were in local hands. There were 24 shares issued worth £500 each. The shareholders were as follows:

- T S Peckston----------- 12 shares

- Henry James Oakes------- 2 shares

- Robert Bevan------------ 2 shares

- George Moor------------- 2 shares

- Abraham Gall------------ 2 shares

- George John Hagget------ 1 share

- Francis George Probert-- 1 share

- William Groom----------- 1 share

- Mary Elizabeth Bullen--- 1 share

Oakes and Bevan were bankers, and Robert Bevan would eventually gain control of the gas company by 1849.

During 1835, another new gasworks was being built at Ely. Ely Gas Company employed Mr George Malam to build the works.

|

| 1836 |

In 1836 Sudburyís leading citizens formed a company to manufacture gas. Sudbury Paving and Lighting Commissioners then awarded the company a contract to provide gas street lighting in the town. The Sudbury company chose contractors George and James Malam to build their plant, the pair having already constructed others in Bury St Edmunds, Ely and Newmarket.

|

| 1837 |

St Mary's church in Bury St Edmunds was fitted with gaslight burners and became a customer of the new gas company.

Meanwhile a new gasworks was being erected at Beccles by James Malam.

|

|

First train to Bury |

|

1846

|

Through 1846 the River Lark navigation enjoyed its last 12 months of prosperity until disaster arrived for it at Bury St Edmunds in the shape of the railway. Navigation company records show that some 10,000 tons of coal and other goods were sent from Kings Lynn to Bury St Edmunds by barge in 1845. By 1852 this trade would have dwindled to almost nothing.

In December, 1846 the long hoped for railway line arrived at Bury St Edmunds from Ipswich, and when the first 90 tons of coal arrived in Bury by train, its price fell by ten percent. It arrived to temporary platforms just east of the bridge over Out Northgate Street, and the current station had hardly been started. Not only was coal now available to the gasworks at a lower price, but haulage charges were much reduced by the fact that the coal had only to be transported a few yards from the railhead to the gasworks.

|

|

Northgate Railway Station by 1854 |

| 1847 |

In November 1847 the new railway station at Northgate Street was opened for business replacing the temporary station just across the road to the east. Along with the station came the so-called wharves for unloading coal and other heavy goods. The Gas Works in Tayfen Road had, until late in 1846, obtained all its coal supplies from the canal wharf at Mildenhall Road. Now it could obtain all the coal it required from the goods yard at Northgate Station.

|

| 1849 |

In about 1840, T S Peckston, the major shareholder in the Bury St Edmunds Gas Light Company, had become insolvent. After spending time in the Fleet Prison for Debtors, he finally filed his petition in Bankruptcy. Among the people who had a claim on Peckston's assets were Oakes, Bevan and Co.'s Bank, who held deeds to land and 6 shares in the company as security for Peckston's loans. Robert Bevan, of the bank, had acquired a controlling interest in the Gas Company by 1849.

He obtained an Act of Parliament, called the Bury St Edmunds Gas Act, 1849, which incorporated a new company called the Bury St Edmunds Gas Company, with power to produce town gas in Bury. Bevan now disposed of all the assets of the old company to the new company, for £8,500. The gas works had been in Tayfen Road since 1834, and by 1849 had sold gas at 10/- per 1,000 cubic feet. Bevan's new company immediately cut the price of gas to 8/4 per 1000 cf, and continued to reduce it in future years. This is the company which would continue to run the Gas Works in Bury into the next century.

Robert Bevan was the new Chairman and the Board was made up of local worthies who had the cash to buy shares.

|

| 1854 |

In 1854 the Haverhill Gas Company's Works was opened in Withersfield Road at Haverhill, by the Stour Brook

|

| 1857 |

Until 1857 Bury gasworks had stored its gas in two simple single tier gasholders. In 1857 the first telescopic gasholder was built for £950, with a holding tank at £619. A telescopic holder had one or more risers or tiers, compared to the single piece construction of older holders. This had the advantage of storing more gas in the same floor area as a fixed tank. Gas continued to be maintained at a constant pressure, due to the weight of the movable upper section. The joint between the two sections was kept safe by a seal of water, while the base section still sat in a well of water.

It seems likely that the telescopic holder replaced one of the two non-telescopic holders.

|

| 1860 |

Bury's Gas works was considerably extended in 1860.

|

| 1869 |

A gas works was built at Brandon by the local company, and Brandon now enjoyed street lighting by gas.

|

|

Gas Works by 1871 |

|

1871

|

In 1871 the Spire of St Johns Church in Bury St Edmunds was struck by lightning. The spire had to be shrouded in scaffolding to make repairs and this gave local photographers the opportunity to take birds eye view photographs of the views from the spire. The view northwards from the spire shows the view over the gasworks towards Station Hill. These pictures are by courtesy of the Spanton/Jarman collection held by the Bury St Edmunds Past and Present Society on their website.

This view shows the telescopic gas holder from 1857 on the right. The leftmost holder may still be one of the single tier original holders from 1834.

|

|

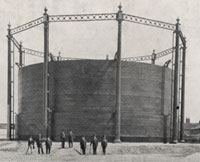

Gas Holder Tayfen Road

Gas Holder Tayfen Road

|

|

1876

|

In Bury St Edmunds gas had been supplied since 1834 by Malam and Peckston's gasworks in Tayfen Road. After several early changes, the works had become owned by the Bury St Edmunds Gas Company since 1849. At this time the gas was used mainly for lighting. Gas cookers would not come into use until about 1897. In 1857 the company had installed a telescopic gasholder, and a further holding tank. By 1876 they needed more capacity, and a new gasholder was built. Because of the restricted size of the original gasworks site, this new gasholder had to be built outside the existing gas works perimeter. The new site was bounded by Tayfen Road and Ipswich Street, so that Ipswich Street ran between the two sites. A picture shows the new Bury Gasworks gas holder being constructed overlooking Tayfen Road, with the Ipswich Arms public house in the background to the right. (This gasholder was referred to as Number 2 gasholder in the company's centenary publication in 1934.) At the same time a new gas purifier was built, and a number of new gas mains were installed in the town.

|

|

Gasholder no 2 completed

|

| 1877 |

With the completion of a second telescopic gasholder, it is likely that the remaining gasholder from 1834 was demolished to make way for the expansion of the gasworks within its original site.

The extra space allowed a new retort house to be built. The extra capacity allowed a programme of new gas main laying to be started.

|

| 1878 |

New capital was issued and shares offered to the public.

|

|

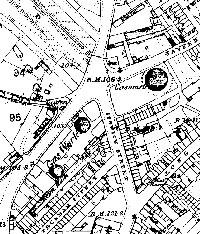

Gasworks and holders |

| 1880 |

This scale 1:2500 map of Bury St Edmunds dates from the 1880s. It shows three gasholders associated with the gasworks at this time. One of the remaining gasholders from 1834 appears to still be in place at this time. Although the map was surveyed in 1883, these features are not always completely up to date.

|

| 1884 |

By 1884, the gas supply in Haverhill was in a poor state. The gasworks had been set up in 1854, but since then the town had expanded ahead of the ability of the gas company to keep abreast. The Haverhill Local board complained that not all the street lights were on when they should be. Individual householders on the gas supply complained that when it was a night with no moon, the demand for gas lighting was such that their lights were no better than rush lights. Such complaints had gone on for over a year.

Matters were more complex because the Haverhill Gas Company had leased the Works to a Mr Goddard for 14 years, which expired at Michaelmas, or 29th September, 1886. Mr Goddard said that there needed to be another gas holder to meet the demand, and the existing ones needed repair. He could not afford to spend up to £2,000 if he were to lose his lease in a couple of years.

The problem remained and 58 ratepayers had signed a petition asking for a public meeting. The Local Board decided to negotiate to buy the Gas works from the Haverhill Gas Company, and made a formal offer.

The Haverhill Gas Company sold its gasworks to Haverhill Local Board later in 1884 for £2,000. It seems that Goddard kept his lease until 1886, or 1887, when the Board took over management of the Works.

|

|

Domestic gaslamp and mantle |

| 1887 |

The earliest gas lights were simple perforated shapes screwed on to the end of the gas pipes. These burners had names describing the shape of the flame produced. These included ratís tail, cockspur, cocks comb, batís wing and fish tail, but the light produced was often poor.

The incandescent gas mantle was invented in 1887 by Carl Auer, a chemist at Bunsen's laborotory in Heidelburg. The specially treated asbestos mantle gave a brighter and more steady light, adding to the demand for gas lighting in domestic premises. Although they were fragile, these mantles gave a much better light.

|

| 1897 |

Gas Cooking was introduced to Bury St Edmunds for the first time in 1897, although gas cookers had first been installed in the Reform Club in London as long ago as 1841.

In 1897 the Bury St Edmunds gas Company agreed to let out cookers on hire for 2/6 per quarter. In an exhibition of gas cookers in April, 5 were sold and 4 taken on hire. By 1934 the company would be supplying gas to 2,660 cookers.

|

| 1898 |

Bury St Edmunds Borough Council sought government permission to borrow £20,000 to open an Electricity undertaking.

|

| 1900 |

At Bury the locals were proud to say that the streets and public buildings would soon be lit by electricity as the works, which belonged to the corporation, were completed in 1900. Under the Electric Lighting Act of 1882, local authorities were empowered to set up electricity undertakings. The generating station, and two cottages to house its key operatives, were located on the Playfields, off Prospect Row. Two Lancashire Boilers were installed driving two 60 kilowatt dynamoes. These produced Direct Current (DC) electricity of three wire 400/200 volts, as opposed to the modern alternating current of 230 volts. By 1903 a further 10 kilowatts capacity was added, and further extensions would be carried out in 1908 and 1910.

During 1900 the first street lighting by electricity was also being installed. At first, there were just eight lighting columns which were turned on early the following year.

In 1900 the Gas Company tried to raise its public profile by opening a Gas Showroom on the Cornhill. It hoped to promote the use of gas cookers, which it had introduced to Bury in 1897. These premises were rented and would close in 1907, to be replaced by a showroom at the gas works itself in Tayfen Road.

|

| 1901 |

The Bury St Edmunds Gas Company had been providing public street lighting by gas since 1834. These needed to be lit each evening by a team of lamp lighters, which was an expensive and sometimes ineffective method. In February 1901 the changoeover from gas to electricity for street lighting would begin. In February the electric street lighting in Bury had its ceremonial switching on. There was at first only eight lighting columns. To assist the change from gas to electric lighting, all the street lamp columns and lanterns were sold to Bury St Edmunds Borough Council by the Gas Company. The Gas Company now relied solely upon supplying gas to households and businesses, and to those public buildings which needed it until they converted to electricity. Gradually people would adopt electricity for lighting, but many preferred to cook by gas right up to the present day.

|

| 1917 |

The First World War brought a halt to most development in this country, and supplies of fuel and raw materials became very scarce, as all possible resources were turned to munitions production.

In February 1917 the gas system failed in Haverhill and the town was in darkness for several days.

|

| 1920 |

The Great War had hindered the modernisation of most industries. The Bury St Edmunds Gas Company now enlarged its operations by installing a fertiliser plant, producing Sulphate of Ammonia from its waste products. It also installed a tar making plant at about the same time.

|

| 1923 |

A reliable thermostat was invented for gas cookers in 1923, and cooking by gas became the preferred method in the town.

During 1923 the Bury St Edmunds gas works was reorganised and enlarged. The original site dated back to 1834, and still contained the manufacturing plant, offices and workshops. It stood on Tayfen Road, hemmed in by Peckham Street, Ipswich Street and St Andrews Street. Also on Tayfen Road, but on the opposite side of Ipswich Street, was the second site, with the control room and the number two gas holder. Opposite to the first site stood the third site, which contained a tar refining plant, and extra storage for coal and coke. The works totalled 3.28 acres over these three sites. The main roads also cut off the plant from the rail sidings, so coal was driven the hundred yards to the works by motor lorries. The last horse was replaced by a lorry in 1920.

|

|

Gasholder no 3

|

| 1933 |

In October, 1933, the Bury St Edmunds Gas Company finished building its new Number 3 gas holder on Tayfen Road. It stood next to the Number 2 holder, and neither of these remain today. The original Bury Gas Works was squeezed into the site at the foot of St Andrews Street North, facing Tayfen Road, whereas these two gas holders were on the second site across the other side of Ipswich Street. Gas was delivered to number 2 and 3 gas holders by a pipeline under Ipswich Street. The number 1 gas holder stood within the walls of the original site and was de-commissioned when number 3 was completed. It was due to be dismantled at an early date.

|

|

The Tar Plant

|

|

blank |

In 1933 a new Tar Refining Plant was erected on the Gas company's third site, opposite the main gasworks. This replaced the 1920 plant, and could produce 10 tons of tar a day, together with lighter oils distilled off during production. An electric crane was used to load and unload drums and barrels from the motor lorries in use. The sulphate of ammonia plant could produce one ton a day, mainly used for fertiliser products.

This third site stood opposite the original site, and contained the tar refining plant and coal and coke stores, but no gasholder at this time. This third site remains associated, at least in part, with the gas industry in 2012.

In addition, the Gas Company had just bought a site in the Traverse for the erection of "up-to-date showrooms."

Nationally the use of gas for street lighting had been in decline, but, nevertheless, by 1933, half the streets in London were still lit by gas.

|

|

Gas Works in 1934

|

| 1934 |

In 1934 the Bury St Edmunds Gas Company celebrated its centenary by publishing a 20 page review entitled "A Century of Progress, 1834-1934".

They supplied tar for roads and paths, sulphate of ammonia and coke, as well as gas from the works at Tayfen Road. The document boasted a modernised works, albeit spread over three sites along the Tayfen Road, 22 miles of town gas mains, and 3,600 consumers. Gas users in Bury had 2,660 gas cookers, 1,500 gas fires and heaters, and 780 water heating appliances. The panorama included shows gas holders numbers 2 and 3 on the left. The characteristic crescent shape of the Ipswich Arms public house can be seen in front of holder number 3. Holder number 1 was now waiting to be demolished, and is visible within the walls of the original works site of 1834. None of the works visible here remains today.

You can view the whole of this centenary document by clicking here:'A Century of Progress, BSE Gas Company 1834-1934'

In October, the Bury Corporation opened its Electricity Showrooms on the Cornhill. The council had generated all the electricity in the town since 1900, at its Prospect Row Works. It seems that the Gas Company was also just about to open a gas showroom in the Traverse in early 1935.

|

| 1935 |

The Gas Showroom opened in the Traverse in Bury's town centre.

|

| 1942 |

Wartime conditions made coal difficult to obtain for the gasworks, and one response to this was to use a new product called water gas. During 1942 a water gas plant was built on the north side of Tayfen Road by the Gas Company. Water gas was made by blowing steam over red hot coke, although the resulting gas was of a lower calorific value than gas obtained by heating coal. The water gas and coal gas could be mixed to produce a usable product. The system had the advantage of requiring no new source of coal, as coke from the coal gas plant could be utilised. This location north of Tayfen Road would become the main focus for future gas improvements. (The gas holder which still stands on this site in 2009 would not be built until 1952.)

|

| 1945 |

In 1945 the Haverhill Urban District Council decided to change the Town Hall lighting from gas to electricity.

|

| 1949 |

The Gas Act of 1948 nationalised 1,064 local gas companies and put them into 12 Area Gas Boards, overseen by the National Gas Council. The Eastern Gas Board was born, and came into operation in 1949.

|

|

Gasholder completed 1952

|

| 1952 |

In the winter of 1951-1952, a new gasholder was built on the north side of Tayfen Road. This was to meet the urgent need for more gas storage capacity, and could hold 750,000 cubic feet of gas. Hitherto, the existing three gas holders could store just 280,000 cu ft, which was only enough to meet 4 hours supply at peak demand. This is the gasholder still standing in 2012, although decommissioned in 2011.

|

|

Gasworks in 1963

Gasworks in 1963

|

| 1964 |

Bury Gasworks in Tayfen Road would close down production in 1964, but the gasholders remained as part of the national grid network. Town gas had been generated here by the process of heating coal to drive off the gas, which was collected in three huge gasometers. Coke was the by-product from this process. By 1960 the cost of gas manufacture became too expensive and a grid main was laid and gas was imported from North Africa via Canvey Island. The Bury St Edmunds Gas works finally closed on April 11th 1964. Coal gas was now supplied from outside the area. Natural Gas from the North Sea would arrive in Bury in 1971.

Although the gasworks itself was closed, the gas holders remained and were integrated into the national grid. They were acting in the same way as they always had, by holding the local supply and distributing it to consumers at the right pressure.

|

| 1965 |

Supplies of natural gas were discovered off the Yorkshire coast in quantities sufficient to make a massive conversion to the use of natural gas possible, and by 1967 a process of converting 20 million gas appliances to use the natural gas began. The national conversion process would last until 1977.

|

|

Gasholder in September 1968 |

| 1968 |

This picture shows the flooding in September, 1968. It shows that at least one of Bury's gasholders in Tayfen Road was still in situ, and appears to be holding gas, and is thus still active. Another photo from the same time shows that despite the gasworks closing in 1964, the gasworks buildings on the Tayfen Road frontage were still on site four years later.

|

|

Gas Works demolition in 1970

|

| 1970 |

This picture is thought to date to 1970, when the redundant gasworks in Bury St Edmunds was being demolished. It had ceased production in 1964. The picture must have been taken from part way up the gasholder built in the 1950s, and finally to be demolished itself in 2016. The house shown was the gasworks office, and had at times also been the gas showroom before it moved to the Traverse.

|

|

Burning off coalgas

|

| 1971 |

Bury St Edmunds had enjoyed a coal gas supply since 1834. The town's own gasworks had closed in 1964, and coal gas was then piped in by a national network, or grid, of pipelines. Following the discovery of vast reserves of natural gas under the North Sea, it was decided to replace gas made from coal by this vast natural resource. Unfortunately every gas burning appliance needed to be converted to run on the new fuel, and there had to be a coordinated changeover, area by area. During 1971 Gascol converted Bury St Edmunds to run on natural gas.

|

| 1973 |

The Gas Act of 1972 brought a restructuring of the nationalised British Gas industry.

The Gas Council was abolished and the British Gas Corporation established. Area Boards became Regions within the new British Gas Plc. EGAS replaced the Eastern Gas Board, (EGB).

|

| 1975 |

A small amount of gas lighting in the streets of Birmingham had survived until 1975. This year saw the removal of those last gas lamps.

|

| 1980 |

In 1980 the Victorian gas holders in Withersfield Road in Haverhill were knocked down.

|

| 1986 |

The gas industry was privatised, under the Gas Act of 1986. This brought the industry full circle, but now the many small companies of pre-1948 were replaced by the monolithic British Gas PLC.

|

| 1997 |

In February, 1997, British Gas underwent a so-called de-merger, and two new companies, called Centrica Plc and Transco were established. Centrica took over the gas fields and the supply of gas. Transco took over the national pipelines and distribution networks

|

| 1999 |

A company called Transco was at this time responsible for controlling the national pipeline network for the distribution of natural gas.In 1999 Transco announced that all local gasholders would be phased out over a ten year period. In fact it would take sevral more years before the process would be completed.

|

| 2005 |

After various bewildering name changes, the transmission of both gas and electricity ended up in a company called National Grid.

|

|

Decommissioned Gas Holder

|

| 2011 |

In April, 2011, the National Grid began a programme of gas mains replacement across Bury St Edmunds. These works would last until the Spring of 2012, and would cause some disruption to traffic flows as roads were excavated, the distinctive new yellow plastic mains pipes installed and roads then reinstated. Work started in Ipswich Street and were scheduled to finish in Eastgate Street and Cotton Lane in late March, 2012.

These gas main improvements were accompanied by the decommissioning of the last gasholder in Bury St Edmunds. This landmark had stood in Tayfen Road since 1952, and its demise was visible as the upper part was sunk to its lowest level, leaving the access ladders sticking up like dead trees.

|

|

Gasholder demolition

|

| 2015 |

In November 2015 the long awaited demolition of the last remaining gasholder in Bury St Edmunds began. Originally scheduled for February, nothing appeared to happen until the Autumn. The gas had been emptied in 2011 and the tank purged before the contaminated water in the gasholder seals could be pumped out and removed for treatment. Then part of the cap was removed in early December.

This picture, taken on the 16th December, shows how the gasholder walls were being cut away and removed off site.

|

|

Gasholder 15th January 2016

|

| 2016 |

By 15th January, 2016, the last remaining gasholder in the town of Bury St Edmunds had disappeared from the skyline. Demilition work had reduced the steel structure down to the last four feet, all accomplished by a large digger equipped with a massive jaw which tore chunks of metal from the structure.

The gas holder, built in 1952, was made up of giant metal cylinders that fit snugly inside each other. It was decommissioned in 2009.

When more gas was added to the holder,the inner rings would rise, meaning the structure could increase in height from eight to 22 metres tall. It held 13 tonnes of gas when at full capacity.

|

Prepared for the St Edmundsbury History website

by David Addy, May 6th 2012

RESOUCES USED

'A Century of Progress, 1834-1934', published by the Bury St Edmunds Gas Company, 1934

Website of the The Gas Museum at Leicester

New website for The National Gas Museum, Leicester

Sudbury Local History Website Sudbury by Gaslight

|